Digital Transformation

‘Pretty much nobody is ready to embark on this transformative journey, so let our team let you know what you need to have Manufacturing 4.0 in you business.

Our Experts in Smart Manufacturing will not bore you with big words, lets talk simple and reach a competitive advantage that will set you apart from the rest of the Executives.

IIoT

IIoT goes beyond simple automation, introducing a new era of connectivity where machines, sensors, and devices communicate intelligently, helping increase efficiency.

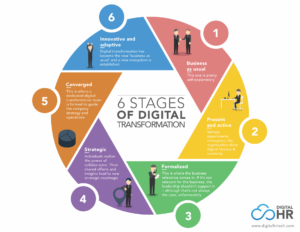

Digital Transformation

It involves the adoption of advanced engineering tools, automation, data analytics, and connectivity to optimize workflows, enhance precision, and improve overall operational efficiency.

Manufacturing 4.0

This transformation aims to optimize production, enhance efficiency, enable predictive maintenance, and foster greater customization and flexibility in manufacturing processes.

IIoT Internet of Things

Join us as we delve into the transformative world of IIoT, unlocking its potential to reshape industries, drive efficiency, and lay the foundation for a connected, intelligent future of manufacturing. The journey into the Industrial Internet of Things has begun – and the possibilities are limitless!

Digital Transformation

Digital transformation enhances operational efficiency, fosters agile decision-making through real-time data, and drives innovation, positioning businesses for sustained growth in a rapidly evolving market.

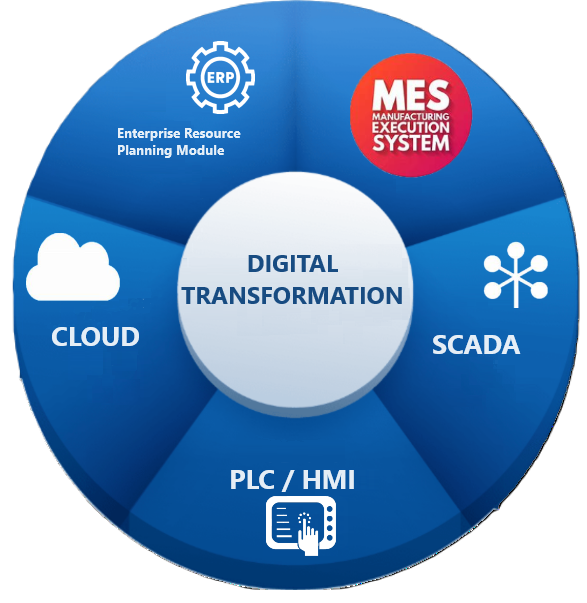

Manufacturing 4.0

What it Requires?

Manufacturing 4.0 uses advanced analytics to turn raw data into actions. Make informed decisions, identify optimization opportunities, and increase you OEE by Reducing Scrap, Increasing Output and Minimizing Downtime.

Digitalization

Engineer the transition from analog to digital workflows in manufacturing, optimizing processes with automation, precision, and efficiency through the incorporation of digital technologies.

Integration

Architect a cohesive integration of digital systems within the manufacturing environment, engineering a streamlined data exchange between machinery, production lines, and control systems to enhance overall engineering performance.

Innovation

Employ integrated digital tools to engineer innovative solutions, driving continuous improvement in manufacturing processes, from product design to production, and cultivating an engineering culture that adapts to technological advancements for sustained competitiveness.

Approach

Industry 4.0 Impact

Stay ahead of the curve! Manufacturing 4.0 isn’t a trend; it’s a strategic investment in the future. Future-proof your business by implementing the latest technologies and methodologies, ensuring your plant remain competitive to other companies.

Experience a new era of precision with smart automation solutions. From predictive maintenance to autonomous machinery, Manufacturing 4.0 ensures your operations run smoothly and efficiently. Minimize downtime, enhance resource allocation, and elevate product quality – all with cutting-edge automation.

Automation in Industry 4.0 isn’t about replacing human workers; it’s about enhancing their capabilities. Our automation solutions integrate with your existing processes, streamlining operations and minimizing manual labor dependency. Experience a level of efficiency that translates to increased productivity and reduced operational costs.

Real-time data in Industry 4.0 provides an immediate and granular view of your operations. Say goodbye to delays in information preparation; empower your decision-makers with up-to-the-minute information.

Contact Us

(664) 244-1759

Blvd Sánchez Taboada Zona Rio Tijuana BC Mexico 22120

Monday-Friday: 9am – 5pm

Get Started

If you want to move towards Manufacturing 4.0 give us a call to make a workplan for you.